Prepping for the 2021 Season

This year, I finally was able to use the winter downtime wisely, spending my time carefully preparing the car having plenty of time to make sure every job was done right and getting lots of testing in to make sure that for the first event of the season, the car is completely ready to go!

Hahahaha! Yeah, right.

The car basically sat on the trailer all winter and I didn’t do anything more than than sort of think about how I should probably be doing stuff to it. For about a month, I had to get it off the trailer and use it as a daily driver since I had a small issue with oil pressure on my truck. That experience was actually a pretty good way to shake it down and see how things are doing! Overall, I have five issues with it that I’d really like to fix:

- Letting off the throttle too suddenly or easing in to the throttle too slowly will cause the car to stall at a stop. that’s really annoying.

- The speedometer doesn’t work

- The fuel gauge doesn’t work

- The tachometer just bounces all over the place

- I’m kind of ignorant on oil pressure

My hope was that the gauge issues would be solved by re-flowing the solder joints on the cluster’s PCB. But I did that and no change, so I’m not sure what’s up with that. I think that the tach problem is a source issue from the Megasquirt, the fuel gauge issue is caused by me screwing up the sender when I replaced the fuel pump, and the speedometer is something else as well.

The oil pressure problem was the easiest to fix. In the process of repairing my truck, I picked up a mechanical oil pressure gauge to check my Harbor Freight tool against. Since it was twenty bucks and just laying about, I picked up the $15 copper hardline kit for it, put a hole in the firewall, and went ahead and installed the system. The old pressure sender wasn’t in the best condition:

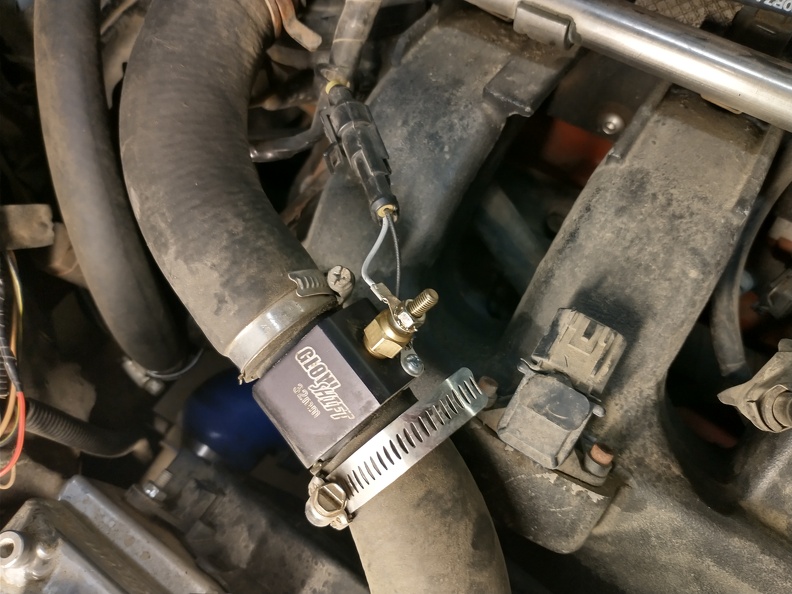

While I was doing gauges, I also replaced the coolant temp sensor and gauge. One of the times that the motor mount broke, the wires got pulled out of the Glowshift sender and there wasn’t really any way to repair that. I had an electric coolant temperature gauge and sender that I bought for the motorhome ages ago, so I brought that over and installed it on the Neon:

I also used one of those weatherpack connectors to re-create the oil temp gauge sender since the existing connectors were just the blade-types and weren’t working too well. Since I was going to the Equus analog gauge for the coolant temperature, I had the opportunity to move the old coolant temp gauge to be the oil temp gauge. The oil temp readout has some busted LED segments, so it required a lot of interpretation.

In addition to putting those gauges in, I also took the opportunity to pull the incandescent bulbs out of them and replace them with some white LEDs that I had laying about for cosplay projects.

I think they wound up looking much nicer:

I also pulled the bulbs out of the gauge cluster and replaced them with white LEDs. It was a lot of work for a car that I don’t really drive at night.

Speaking of driving the car, I also began this process:

Yes! That is an actual door panel installed on the car! With door sill trim! I even have a brand new carpet sitting on the shelf, ready to go in. Fancy, isn’t it? I had to go ahead and fix up the door handle mechanism on the inside since the rules dictate that you have to be able to open the door from the inside. Since I was doing that anyway, I decided to put the door panel on. And in order to do that, I decided to also fix the window guides. So now I have all the door trim on, the windows roll up and down properly, and all the weatherstripping is in place. When you close the door it has a very satisfying “thunk” instead of the old “bang, rattle, rattle, rattle, rattle”. It also turns out that 97.6% of all of the rattling around noises that the car used to make going down the road was coming from the windows banging about in the doors. It’s much more pleasant to drive and I still don’t have any rear trim or seats installed, and there’s no carpet or headliner.

I don’t want to put the carpet in until I’ve decided what to do with the front seats. Originally, I wanted to get a couple Corbeau Forza seats, but if I’m going to have a rear seat installed, I’m going to need at least one seat to be able to fold down for access. I have the Corbeau brackets so I was holding out for those seats, but I may leave that behind and move a different direction. I need to choose from:

- Fixed-back seats on sliders for both fronts and rear passengers can squeeze

- Folding-back seats on sliders for both fronts to add some bolstering for racing but maintain the back seat access

- Leave the seats as they are

- Fixed-back seat for the driver and the stock seat for the passenger

Once I work that out, I can pull the seats and put in the carpet, rear seat, and the rest of the trim.

Another small change that I made to Toiletbird Industries was this:

That’s a Titan Lifts 6,660lb scissor lift that will raise the car about 4 and a half feet. It makes everything a lot easier, especially the pre- and post- race inspections. With the car up over my head, I was able to get in there and really look at the front motor mount. It’s still looking absolutely solid with no signs of any cracking, bending, or other deformation.

On the topic of the speedometer, I went ahead and pulling the sender off and felt around in the transmission. It feels like the ring gear on the differential is still solidly in place, so it’s got to be the sender, the wiring, or the cluster. The sender is getting power but I don’t know if it’s sending a signal. I’ve got a USB oscilloscope on the way right now that I’m going to use to see if I can watch the signal coming out and then track it back. I could try hooking a drill up to the sender to see if it makes the speedometer move, but then I wouldn’t need a new tool.

Now that I can get the car in the air, I may try to run the car low on gas – a bit of a trick when you don’t have a fuel gauge OR an odometer! – and then pull the fuel pump assembly out to check the grounds and the sender. It would be really nice to have functioning gauges.

I had the car basically ready for what was supposed to be the first points event for 2021, but it got cancelled (or postponed, I guess) due to rain. But now I know it’ll be ready for the second event! It’s also got to be ready for Nationals this year. Turns out it’s going to be held right up in Ross County, OH, so there’s really no excuse to not be there.